At present, the new energy vehicle market is in a rapid development stage. And Chinese new energy automotive electronic market is growing rapidly in these years, it's expected that will grow to 1097.3 billion yuan in 2023. The intelligence and electrification of the automobile also promote the growth of the global automotive electronic market.

Forecast of Chinese Automotive Electronics Industry

(Data source: automobile industry association, China Commercial Industry Research Institute)

In order to pursue lighter weight, more intelligent control system, and reliable operation in harsh environments, the components for the automobiles must be certified or predefined to ensure that the failure is within the acceptable range or in accordance with regulations. Therefore, on board components must have high reliability, low loss and temperature stability.

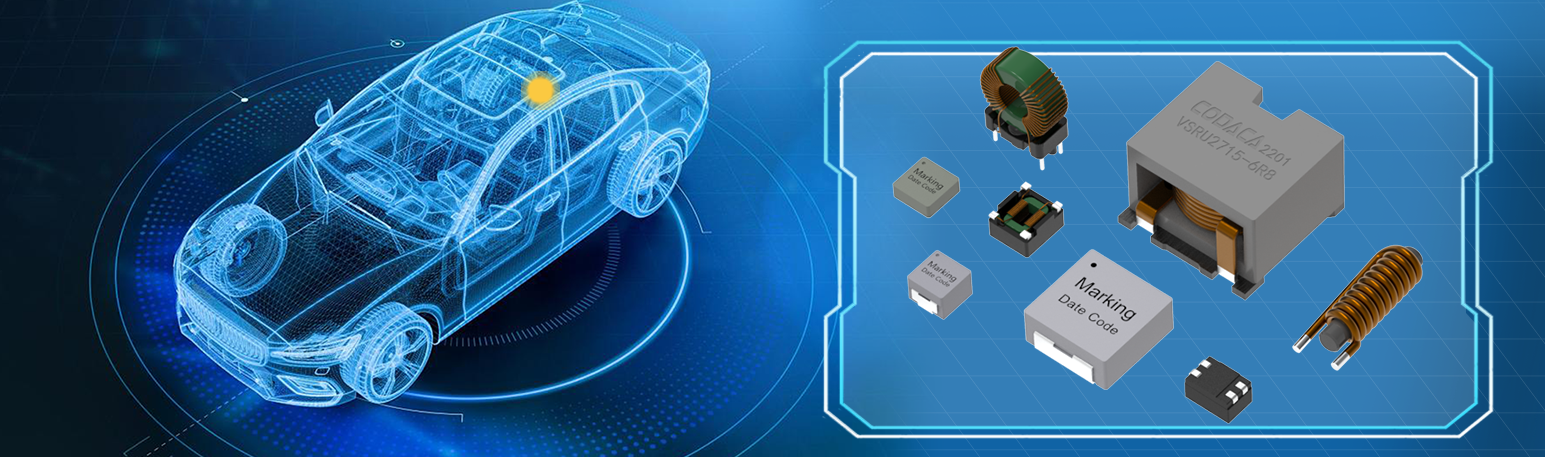

CODACA - a professional power Inductor manufacturer has developed series of automotive grade power inductors with high reliability, high current, and low loss through in-depth cooperation with automotive electronic

customers, providing solutions for automotive electronics applications such as car lighting, automotive on board charging(OBC), battery management system(BMS), DC-DC converters, smart carbine, ADAS, T-box, V2X, etc.

(Image source: CODACA Inductor)

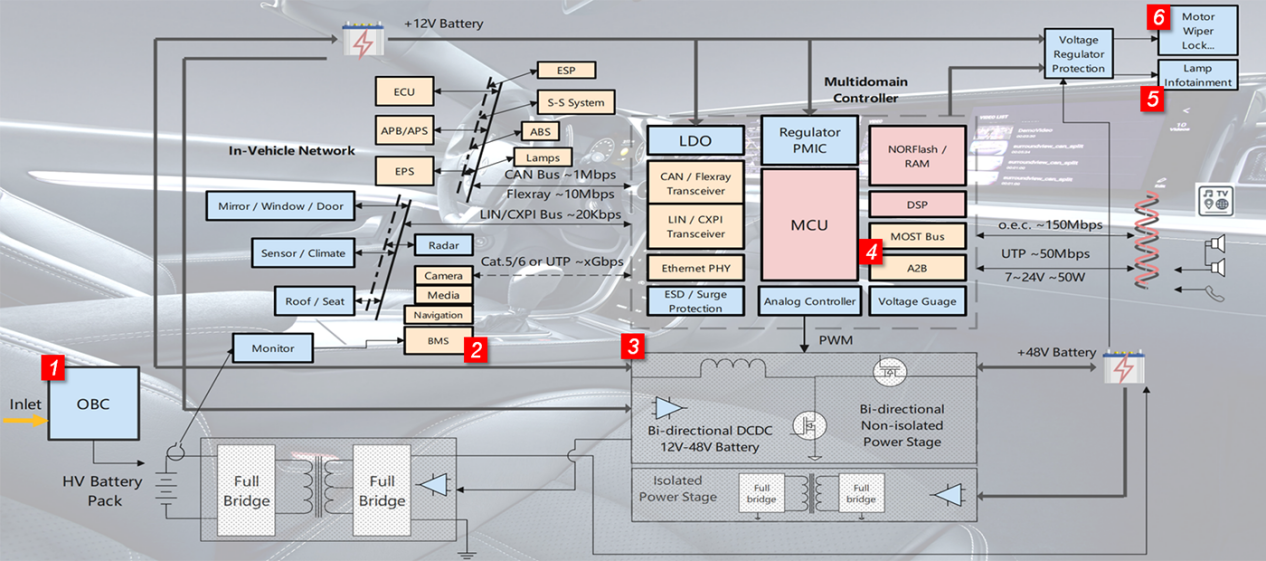

1 OBC - on-board battery charger 2 BMS - battery management system 3 12-24V low-voltage two-way battery system | 4 A2B and MOST for on-board digital audio 5 Vehicle lighting, infotainment, electronic load 6 On-board motor driver |

1. OBC - On Board Charger

Many different topology had been developed for OBC application to pursue higher power density and conversion efficiency as well as faster charging cycles. As vehicle to grid units, there is always PF (Power Factor) qualification and EMC regulations bringing the needs of lots of bulky filter elements and power chokes. It is also important to implement necessary filter stages on secondary side of bridge transform-in and other auxiliary sides so that to tame the significant harmful noises which could late be risky to overall charging system.

Recommended Power Inductors for Onboard Battery Charger: TCB/VSAB/VSRU/VRKL/CSTC/CSTA/VSHB/VSEB-H

They designed with high-reliability, high-temperature, and low loss to offer the best overall efficiency for on-board charger applications.

2. BMS - Battery Management System

High voltage battery packs in modern EV/HEV needs to be safely and efficient supervised from being early ending up with service time and possible over temperature, over current or over voltage risky oper- ation failures. Thus, BMS has to monitor and balance battery units simultaneously to maximumly tame the charging risks and optimizing the service life. The necessary sensor networking, switching control circuits and braking switches brings up many isolation and filter components to that reason. It is also important that long stable life cycles of the parts been applied to less the maintenance costs.

Recommended Power Inductors for BMS: VSHB / VSEB-H / VSAB / VSRU

They qualified with AEC-Q200 grade 0, and feature a magnetically shielded structure resulting in excellent resistance to electromagnetic interference and minimizing the audible buzzing noise as well.

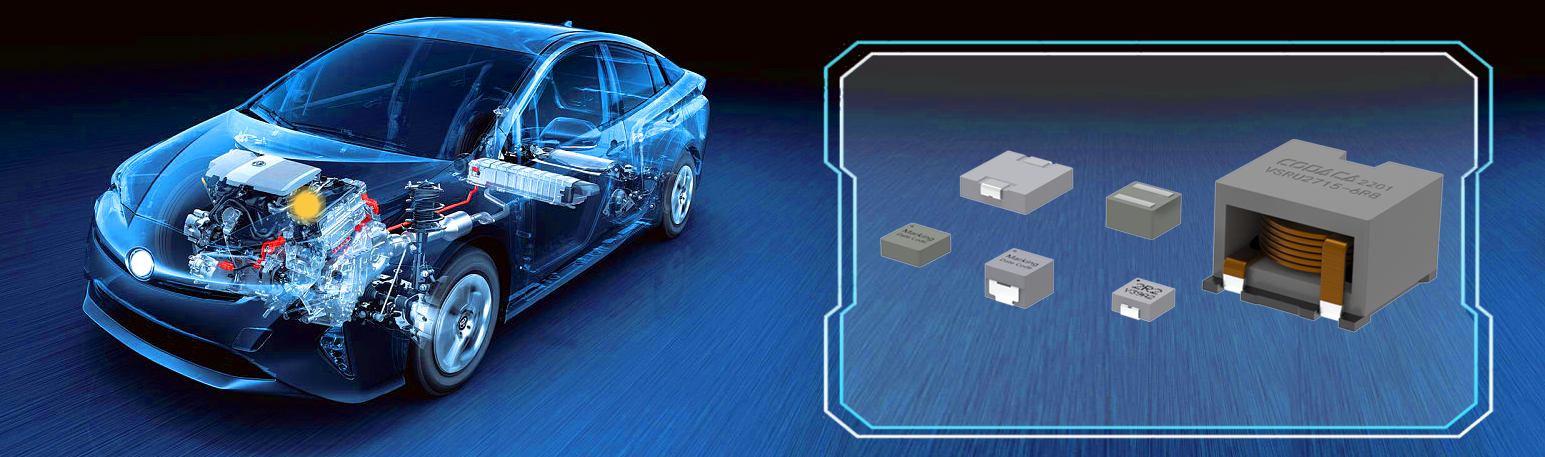

3. 12V/48V Bi-directional Battery System

Many electronic loads in car are 12V driven while today’s battery line has come to a combination of 48V for enhanced bus and additional power efficient supplies, of which in EV/HEV the 48V battery will be charged from high voltage battery pack or traction battery. To fulfill the different voltage buses the 12V-48V bi-directional power conversion is populated in power system in car body and both of the two have isolated or non-isolated DCDC converters down the road which are serving the in field powering on for different functional units’ requirements.

Recommended Power Inductors for 12V/48V Bi-directional Battery System

VSRU / VSAB / CSTA / CSTC / VSHB / VSEB-H

The high-performance molded power inductor offers the best overall efficiency for automotive applications. The molded construction is the best solution to achieve maximum power density.

VSRU series high current power inductor designed with flat wire and feature high saturation current, low loss and low DC resistance.

4. A2B and MOST for On-board Digital Audio

A2B is Analog Devices, Inc. protocol for high bandwidth, bi-directional digital audio bus network. It utilizes single pair of UTP (Unshieled Twisted Pair) for transporting data and power at the same time. It simplifies digital audio sub networks in vehicles as well as powering the nodes, so that to achieve lighter and simpler invehicle audio distribution.

MOST is traditional media network bus in car which has higher data rate and could be configurated with different transmitting medium such as optical fiber, coaxial or UTP wires.

Recommended Power Inductors for A2B and MOST for On-board Digital Audio

High current power inductor for AMF CPD series: provide higher current and lower loss. This unique design saves space while maintaining exceptional audio performance.

Super high current power inductor CPE/CSD/VSRU series: Flat wire design feature soft saturation, low loss and low DC resistance.

Molding power Inductor VSAB /VSHB / VSEB-H series: Qualified with AEC-Q200 grade 0, molded by low loss alloy powder with the feature of lower DC resistance and effectively reduce the risk of layer-to-layer short.

5. Car Lighting Infotainment Electronic Loads

EVs/HEVs as exampled are designed in more intelligent manner and comfortable sensitive for commercial vehicles with functionaries such as ADAS, ACC, APS, infotainment, AI assist, auto lights, etc. As of this kinds of demand increasingly emerging on market or upgraded by generations, more and more electronic loads in car which also pushing for increasing power drivers to supply power from battery system.

Recommended Power Inductors for Car Lighting Infotainment Electronic loads

VSRU / CSBX / CPU / CPQ / CPAG / CSTA / CSTC / SPRH Series: high-performance, low loss power inductors offer the best overall efficiency for automotive applications.

VSAB /VSHB / VSEB-H: the high-performance molded power inductor offers the smallest volume but the best performance for car lighting, infotainment or ADAS applications.

6. On-board Motor Drive Device

The new passenger car integrates rear side camera, lane anti-collision alarm, door/window lock, roof view, or other electronic control equipment, all of which are driven by on board motors. They are connected via the bus and always in standby state when the engine is started. This is also where several different DC-DC converters work later to meet the power demand.

Recommended Power Inductors for On-board Motor Drive Devic

VSHB / VSEB-H / VSRU / VSAB / CSTA / CSTC / VRKL

They designed with high-reliability, high-temperature, and low loss to offer the best overall efficiency for on board motor drive device applications.

CODACA provides R&D services and technical support for customers to select appropriate power inductors through close cooperation with automotive electronics R&D engineers. We focus on the research and development of magnetic materials and the design optimization of coils and inductors to reduce the power loss in the voltage conversion/filtering process. CODACA has a laboratory certificated by CNAS, which can independently test and certify according to the AEC-Q200 passive component product validation standard, and can provide PPAP according to customer requirements for the convenience of selection and approval by end customers.